Auto Body Welding

Sunke produces customized welding controllers and transformers to meet your different needs for car body welding.We provide customized auto body welders for the automotive manufacturing industry. enabling companies to achieve high-quality welding and advance your smart auto manufacturing transformation.

Application Scenario

Resistance welding technology plays an important role in automobile manufacturing. Auto body welding mainly includes spot welding, multi-spot weding, seam welding, and projection welding. and has been widely used in connecting automotive parts such as doors, floorboards, tanks, front axles, body assemblies, and engine hoods. The auto body welding technology can not only improve manufacturing speed and productivity, but also ensure the strength and sealing ofthe welds, thereby improving the quality and reliability of automobiles.

Application Display

Optimize Your Auto Body Welding with Advanced Solutions

Aluminum weldingfor automotive applications

Steel weldingfor automotive applications

BIW welding

Our partners

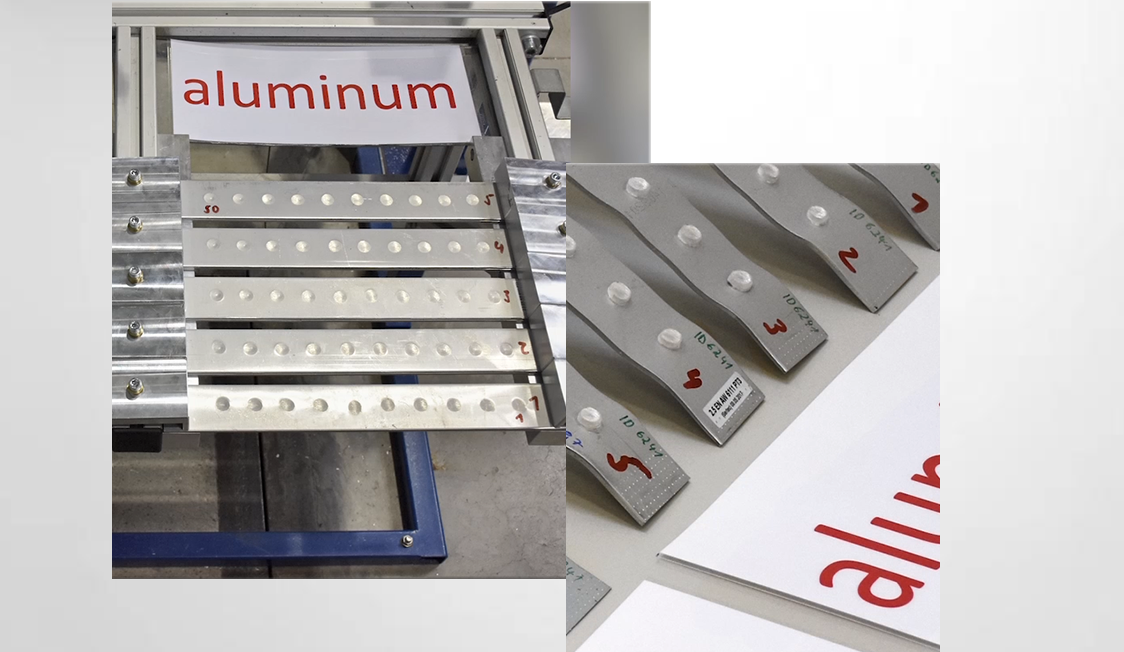

Aluminum weldingfor automotive applications

Common Challenges in Auto Body Welding: • Resistance spot welding struggles with aluminum shunting. • Variable surface conditions lead to inconsistent results.

Innovative Solutions for Aluminum Welding

• High Welding Current: Boost weld strength and consistency. • Short Welding Time: Enhance precision without compromising quality. • Adaptive Regulation: Minimizes solder joint inconsistencies caused by material variability. • Regular Electrode Cleaning: Ensure consistent performance and extend equipment life.

Steel weldingfor automotive applications

Common Challenges in Auto Body Welding: In the realm of auto body welding, particularly when working with galvanized steel, unique challenges often arise. Issues such as low welding current density, zinc layer burn-off, and electrode contamination can significantly reduce efficiency and electrode lifespan. Additionally, the low resistivity of the zinc layer and small contact resistance often lead to defects like welding spatter, cracks, and porosity.

Innovative Solutions for Steel Welding

• Rapid Parameter Setup via DB Database: Configure welding parameters across the entire production line quickly and efficiently. • Online Monitoring for Quality Assurance: Real-time monitoring and analysis of welding quality through an intelligent controller system. • Adaptive Welding Technology:Adjust the solder parameters according to the dynamic resistance value to achieve precise and defect-free solder joints.

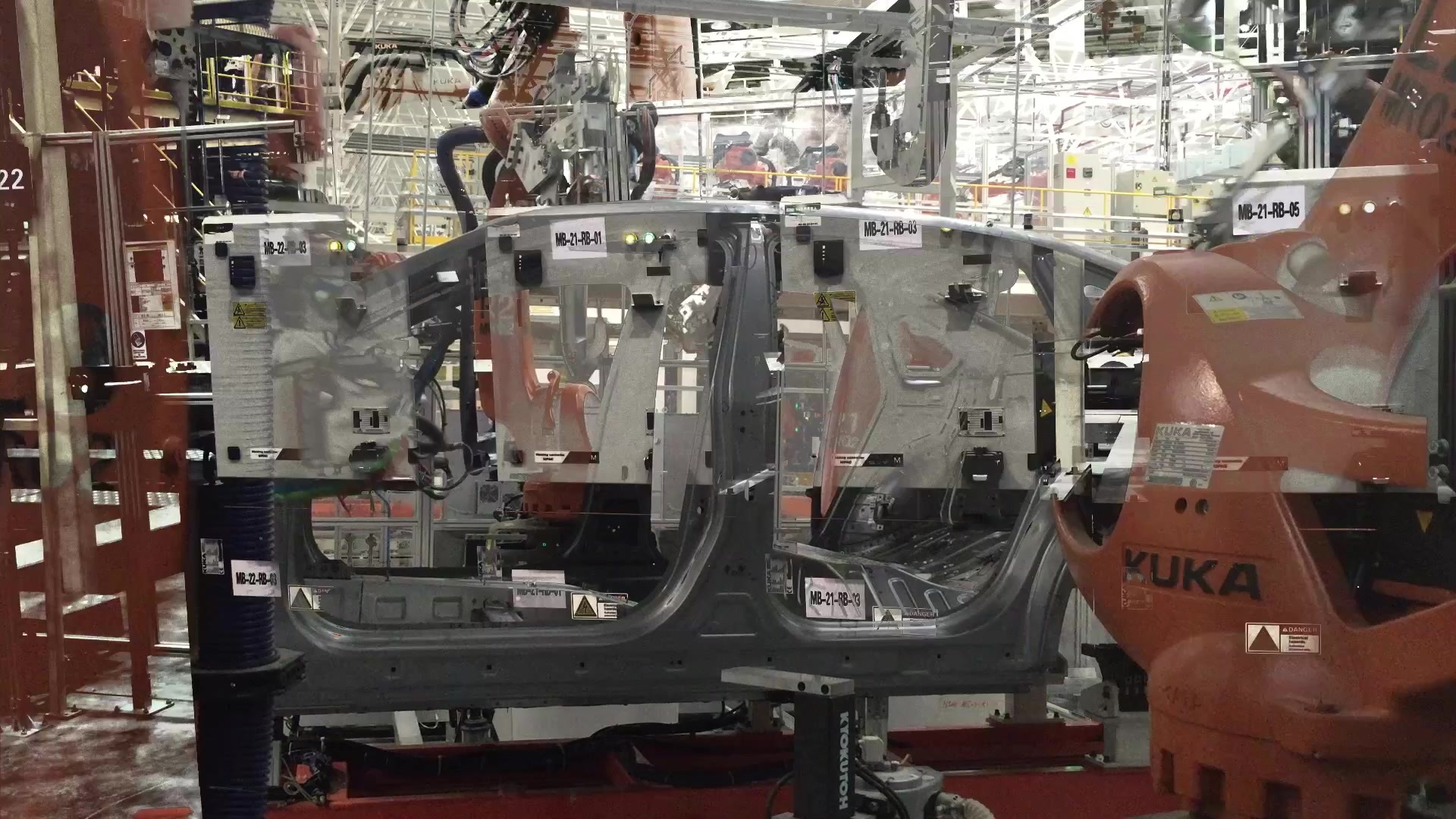

BIW welding

The intermediate frequency robot resistance welding controller can precisely control the robot welding tongs, and adopts intelligent self-adaptive technology to effectively prevent spatter during welding.

Our partners

Over the course of 40 years of development, we are firmly in a leading position in the auto body welding market through close collaboration with top domestic and international automobile manufacturers. Sunke is committed to continuously increasing our investment in R&D, constantly exploring new technologies and applications, to deliver more precise and comprehensive auto body welding process solutions for our partners. At the same time, we look forward to establishing partnerships with more individuals and organizations, jointly creating a bright future for intelligent car body welding.