Industrial application

In industrial applications, resistance spot welding is mainly used to weld sheet metal and wire mesh, seam welding is widely used in oil drums, radiators, aircraft and automobile fuel tanks

Application scenario

In industrial applications, resistance spot welding is mainly used to weld sheet metal and wire mesh, seam welding is widely used in oil drums, radiators, aircraft and automobile fuel tanks

Application display

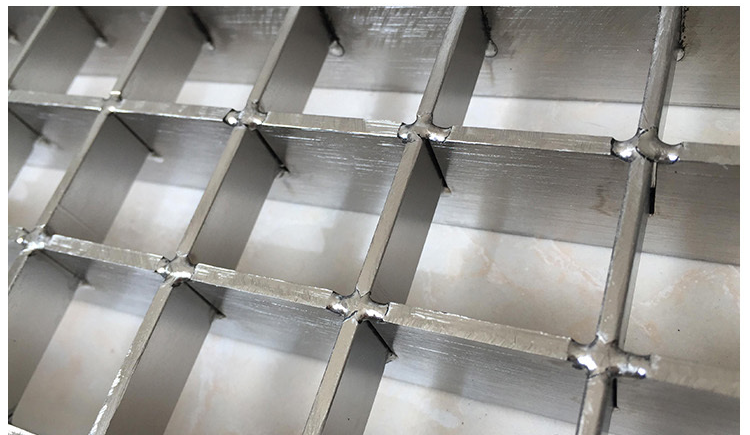

Steel grid plate welding

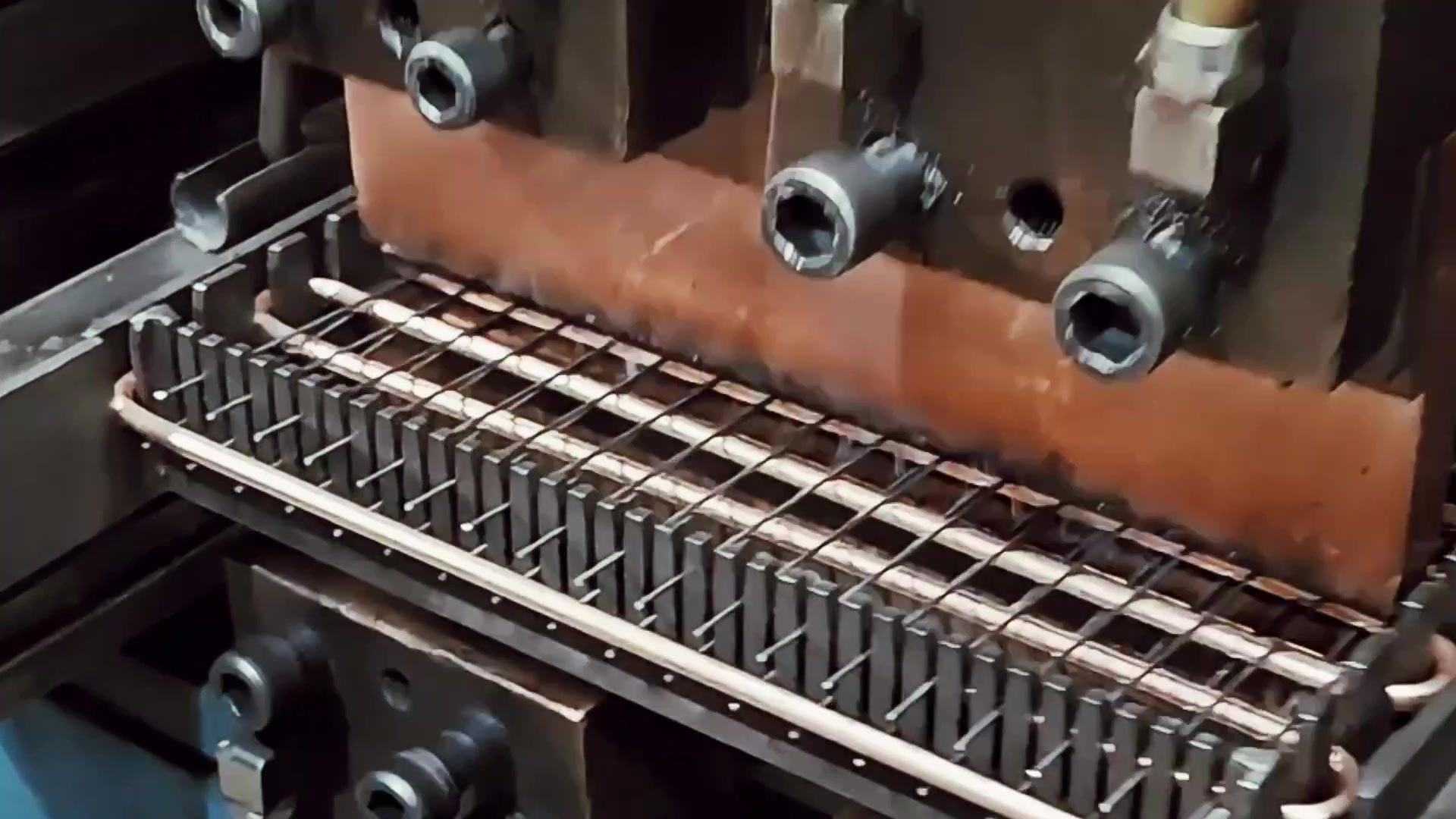

Chain welding

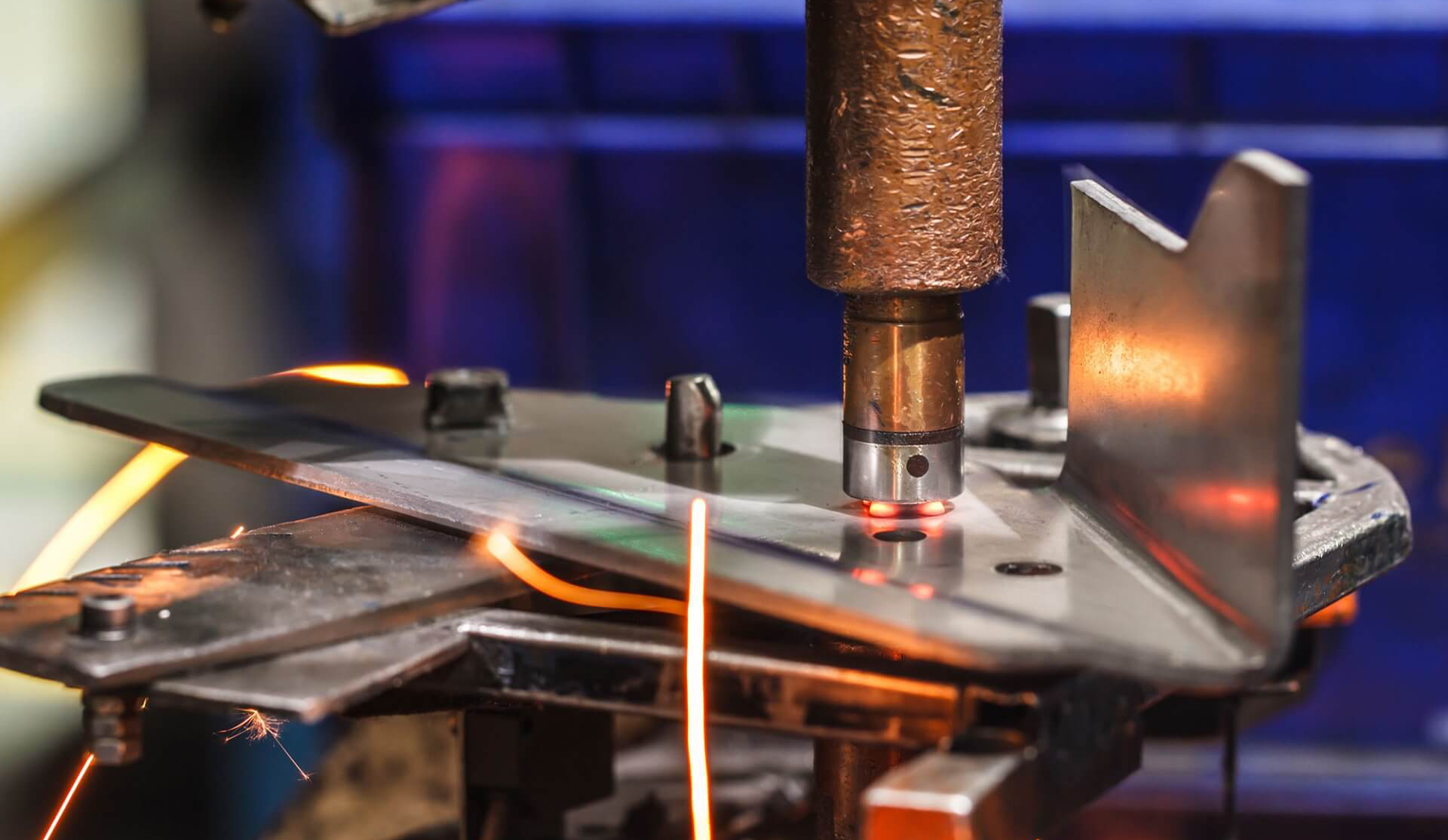

Welding sheet metal parts

Packing drum

Condenser welding

Fuse Welding

PE Pipe Steel Frame Welding

Bolt Projection Welding

Compressor Shell Welding

High-Speed Seam Welding

T-Joint Welding

Hydraulic System Oil Tank Welding

Steel grid plate welding

Using large current one-time forming welding, high production efficiency, stable solder joint, beautiful appearance.

Chain welding

Resistance butt welding, welding speed, high production efficiency, welding strength can reach the base metal strength

Welding sheet metal parts

Continuous spot welding or seam welding is used to ensure the quality of the weld seam when welding sheet metal structures. When welding thicker plates, the current and voltage need to be adjusted according to the type of plate, and a stepwise full welding method and a reasonable welding sequence must be used to ensure structural strength and reduce deformation during welding.

Packing drum

When it is necessary to weld parts with high sealing requirements such as oil tanks and water tanks, the flat welding method with a groove can be used. This method can not only improve production speed, but also ensure the beauty of the weld and the air tightness performance of the parts, thereby ensuring that the sealing performance of the parts meets the requirements.

Condenser welding

Resistance welding technology is widely used in the manufacture of equipment for cooling and condensation processes, such as coolers, evaporators and heat exchangers, which are core components in refrigeration systems such as refrigerators and safes.

Welding method

Welding of steel wire coils in important welding parts, using multi-spot welding

Fuse Welding

Nickel-plated copper fuse internal phosphor bronze sheet spot welding, ensuring a strong welding effect, maintaining an attractive appearance without deformation.

Technical Requirements

Ensure reliable and effective disconnection in the event of short circuits and overloads.

PE Pipe Steel Frame Welding

PE pipe steel frame resistance welding is mainly used in fields such as municipal water supply, natural gas transportation, and chemical pipelines. This welding method has advantages such as fast welding speed, high production efficiency, and stable joint quality, making it suitable for large-scale industrial production.

Bolt Projection Welding

Bolt Projection Welding is a commonly used metal joining technique. By setting projections at the bottom of the bolt, it provides a stable contact surface and even heat distribution during the welding process, resulting in a high-strength and highly reliable connection. This technology is widely applied in the manufacturing processes of the automotive, electronics, and appliance industries, enhancing production efficiency and product quality.

Compressor Shell Welding

The compressor shell is welded by spot welding process, and the solder joints are firm and reliable.

High-Speed Seam Welding

High-speed seam welding is used for the welding of long continuous welds, and is suitable for workpieces that require efficient production and high strength requirements.

T-Joint Welding

High-Strength T-Joint Welding with Sunke MFAC Resistance Welding Controller

Our Solution

Using Sunke MFAC resistance welding controller, projection welding technology is used to ensure: ✔ Precise control of heat and current for uniform weld strength ✔ Spatter-free welding to improve overall weld aesthetics and quality ✔ Seamless integration with automated production lines for large-scale production

Hydraulic System Oil Tank Welding

Welding process for a small hydraulic oil tank. Stable current control ensures clean and consistent weld seams, meeting the strength and sealing requirements of hydraulic systems.