The Sunke Welding System: A Revolution in Accuracy

Release Time:

2025-07-22

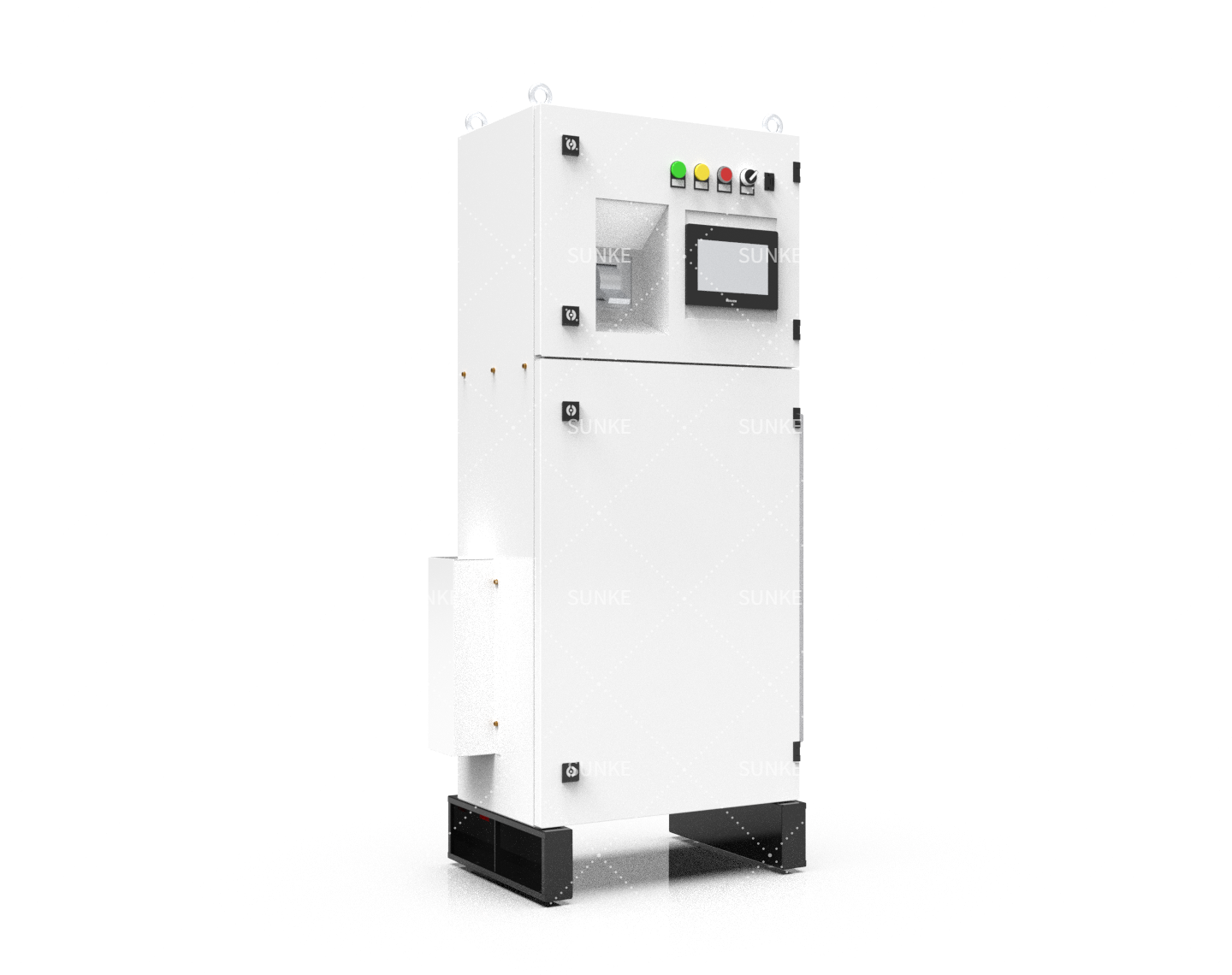

We at SUNKE are committed to pushing the boundaries of welding technology so that it can adapt to the dynamic demands of the manufacturing sector. The MFDC Welding Controller, our most famous product, is proof of our dedication to excellence and new ideas. Typically found in high-precision manufacturing settings, these medium-frequency DC welding controllers work in tandem with welding machines. Spot welding, projection welding, and seam welding are just a few of the many welding applications made possible by their reliable modular architecture, which is compatible with a wide range of metallic materials.

The Power of MFDC Welding Controllers

Our MFDC Welding Controller is engineered for excellence, making it an essential tool for any resistance welder. Medium frequency DC welding controllers are designed to deliver precise DC welding current control, enabling us to achieve optimal results across various applications. These controllers support primary/secondary current control modes, providing customers with greater flexibility in managing the welding process. Whether we are working on automated systems or manual setups, our MFDC controllers adapt seamlessly to both environments. They are particularly effective in fixture-based spot welding systems, where precision and reliability are crucial. With options for air cooling and water cooling, these controllers can be tailored to suit different operational environments, ensuring optimal performance whatever the conditions.

Enhancing Efficiency with Advanced Features

At SUNKE, we understand that efficiency is key in today’s competitive market. Our MFDC Welding Controller incorporates flexible communication interfaces that ensure effortless connectivity with various industrial field buses. This feature allows for real-time monitoring and control, enabling us to maintain the highest standards of quality and efficiency. By integrating our resistance welding equipment with these advanced controllers, we can streamline our operations and enhance productivity. The ability to monitor parameters in real-time means we can quickly address any issues that arise, minimizing downtime and maximizing output. This efficiency is essential for businesses focusing on high-volume production, where time and precision are critical.

Versatility in Welding Applications

One of the standout features of our MFDC Welding Controller is its versatility. Medium frequency DC welding controllers are ideal for a wide range of applications, and we take pride in offering solutions that adapt to various needs. From spot welding to projection welding, our resistance welding equipment is designed to handle it all. This adaptability not only makes our welding controllers suitable for different projects but also positions them as a valuable investment for businesses looking to enhance their operational capabilities. With the right tools, we can tackle a variety of materials and welding techniques, ensuring that we meet our clients’ diverse requirements.

Conclusion

In conclusion, SUNKE stands at the forefront of welding technology with our innovative MFDC Welding Controller. Designed to meet the demands of precision industrial fields, our medium frequency DC welding controllers offer unmatched performance and reliability.