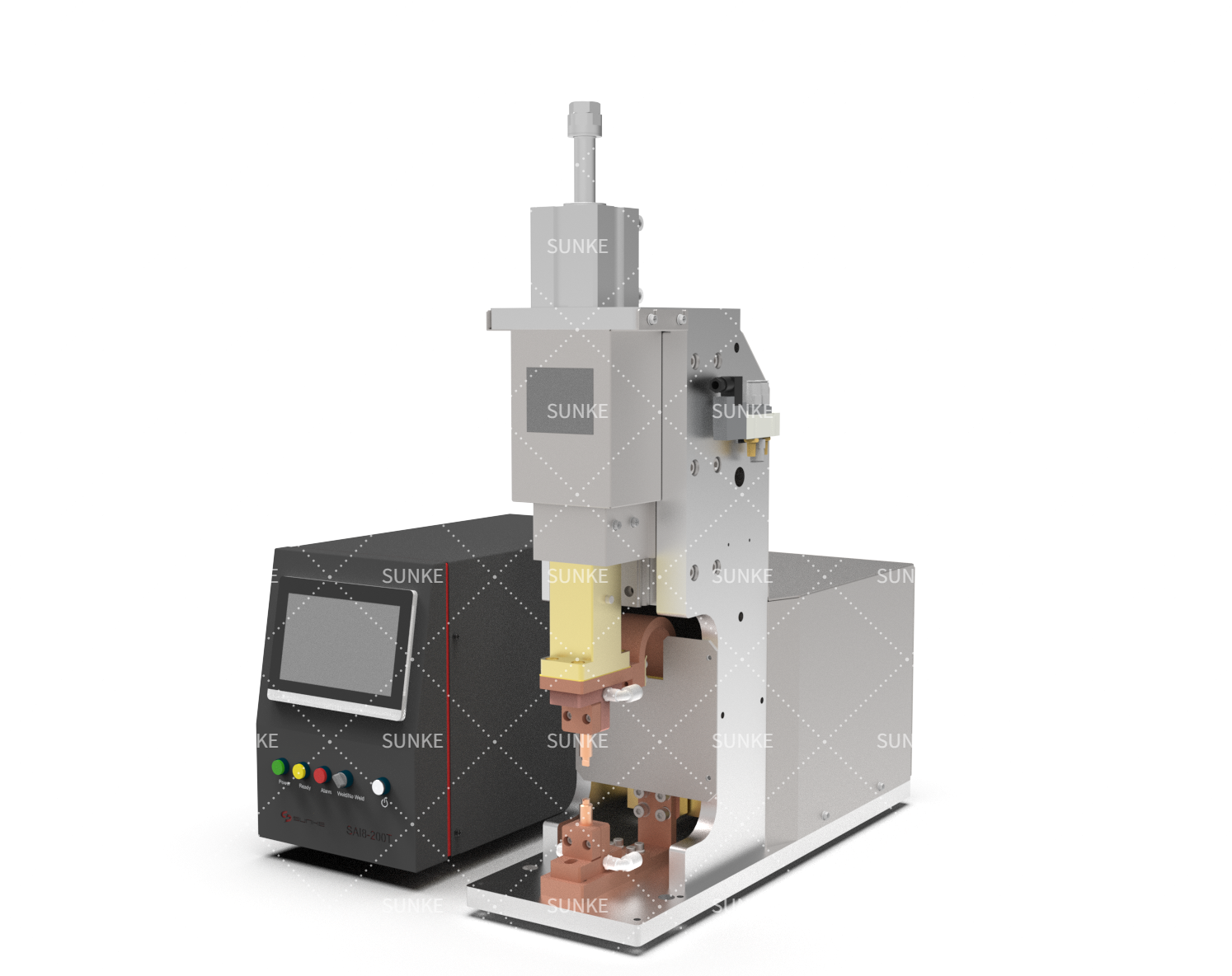

Introducing SUNKE: Revolutionizing Precision Welding Solutions

Release Time:

2025-08-16

At SUNKE, we pride ourselves on providing reliable solutions in the world of precision welding. Our commitment to engineering excellence has led us to develop high-precision welding systems that cater to the most demanding industries, including electronics, automotive, and medical device manufacturing. With our advanced technology, we ensure that our clients achieve exceptional accuracy and consistency while optimizing production costs and enhancing efficiency.

Unmatched Accuracy and Consistency

SUNKE’s precision automated welding systems are engineered to handle even the most intricate welding tasks with exceptional accuracy and consistency. This is not merely a claim; it’s a promise backed by our rigorous testing and quality assurance protocols. Our high precision welding system guarantees that every weld meets the highest standards, ensuring durability and reliability in every application.

With a focus on industries that demand perfection, we’ve designed our equipment to adapt to various welding requirements seamlessly. Whether you’re working on delicate electronic components or robust automotive parts, our systems deliver optimal results, minimizing waste and maximizing productivity.

Innovative Touch Screen Interface

One of the standout features of SUNKE's high precision welding system is our user-friendly Touch Screen Interface. This innovative design simplifies operation and enhances control, making it easier for operators to adjust settings and monitor processes in real-time. Our interface allows for quick navigation through various functions, empowering users to customize their welding parameters with ease.

This intuitive approach not only boosts operational efficiency but also reduces the learning curve for new operators. By integrating advanced technology with a simple user experience, we ensure that even complex tasks can be performed with confidence and precision.

High Current Accuracy for Flawless Welds

In the world of welding, precision is paramount. SUNKE’s precision welding systems are designed with high current accuracy, providing precise control with a 10A tolerance. This level of control ensures consistent welding results across different materials and thicknesses, allowing manufacturers to maintain high quality in their production processes.

The reliability of our high precision welding system means fewer reworks and reduced downtime. As a result, our clients can focus on scaling their operations without compromising on quality. By choosing SUNKE, businesses can enhance their production capabilities and achieve new standards of efficiency and excellence.

Conclusion

In summary, When it comes to precision welding, SUNKE is committed to always being one step ahead. Our high precision welding system are engineered to meet the rigorous demands of various industries, offering unmatched accuracy, innovative features like our Touch Screen Interface, and precise control over welding parameters. By investing in SUNKE’s solutions, companies can significantly enhance their production capabilities, reduce costs, and achieve exceptional results.