Revolutionizing Welding: Introducing SUNKE's MFDC Welding Controller

Release Time:

2025-08-16

Here at SUNKE, we're committed to changing the way welding is done. We have created reliable solutions to address the unique challenges of contemporary production thanks to our dedication to quality and innovation. Here we will present our main product line, with an emphasis on the MFDC Welding Controller and its critical function in high-precision industrial settings.

What is an MFDC Welding Controller

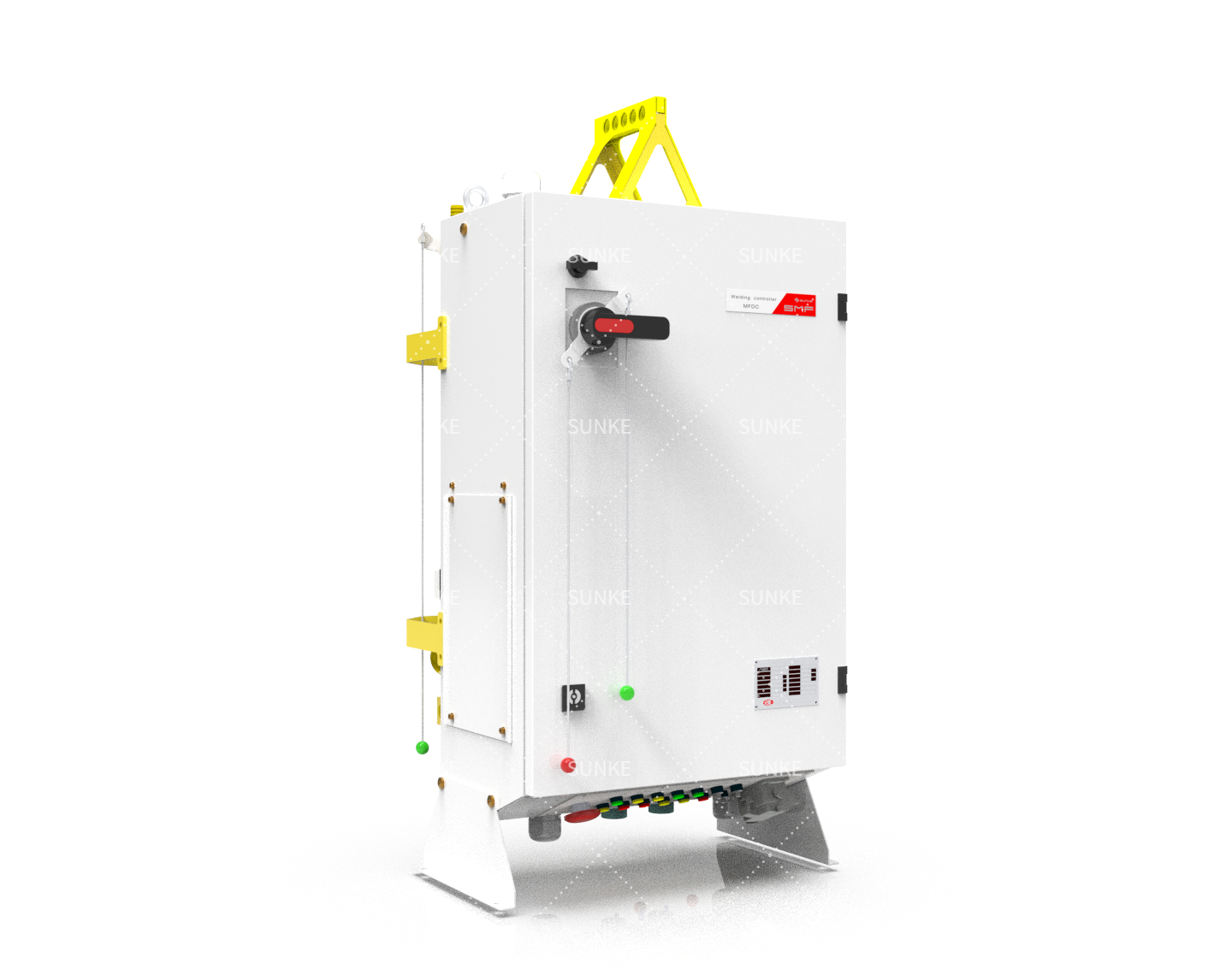

The MFDC Welding Controller is at the heart of our welding solutions. Medium frequency DC welding controllers are used in conjunction with a welding machine and are widely applied in precision industrial fields. These sophisticated devices allow for precise control of the welding process, ensuring that each weld is strong and reliable. With advanced modular design, our controllers ensure compatibility with diverse welding applications such as spot welding, projection welding, and seam welding for various metallic materials.

We understand that different welding environments have unique requirements. That’s why our medium frequency DC welding controllers are designed for both automated and manual welding setups, as well as fixture-based spot welding systems. This versatility makes them an essential tool for any manufacturing operation, whether you are performing high-volume production or specialized tasks.

Features that Set SUNKE Apart

What distinguishes our MFDC Welding Controller from the competition? One of the standout features is our focus on delivering precise DC welding current control. Our controllers support primary and secondary current control modes, allowing you to fine-tune the welding process according to your specific needs. This flexibility is critical in ensuring that your welding operations maintain the highest standards of quality and consistency.

Furthermore, our controllers are equipped with options for air cooling and water cooling, making them adaptable to various operational environments. Whether in a hot, industrial setting or a cooler workshop, our welding controllers perform optimally, ensuring that your production line runs smoothly and efficiently.

Seamless Integration and Connectivity

In today’s fast-paced industrial landscape, connectivity and real-time monitoring are essential. SUNKE’s medium frequency DC welding controllers feature flexible communication interfaces that ensure effortless connectivity with various industrial field buses. This capability allows for real-time monitoring and control, enabling operators to make informed decisions quickly.

The integration of our weld control into existing systems is straightforward, minimizing downtime and maximizing productivity. Additionally, our solutions are designed to work seamlessly with a variety of welding machines, ensuring that your operations remain efficient and flexible.

Conclusion

At SUNKE, we pride ourselves on setting the benchmark in the industry for reliability and performance. Our medium-frequency DC resistance welding controllers are tailored to meet the demanding needs of modern welding processes. Whether you require an MFDC welding machine or a comprehensive middle frequency DC welding controller solution, we have you covered.

With SUNKE, you can expect precision, efficiency, and durability in all our products. Trust us to provide the welding solutions that meet your industrial challenges today. As we continue to innovate and enhance our offerings, we invite you to explore how our welding controllers can transform your welding operations and achieve the excellence your business deserves.