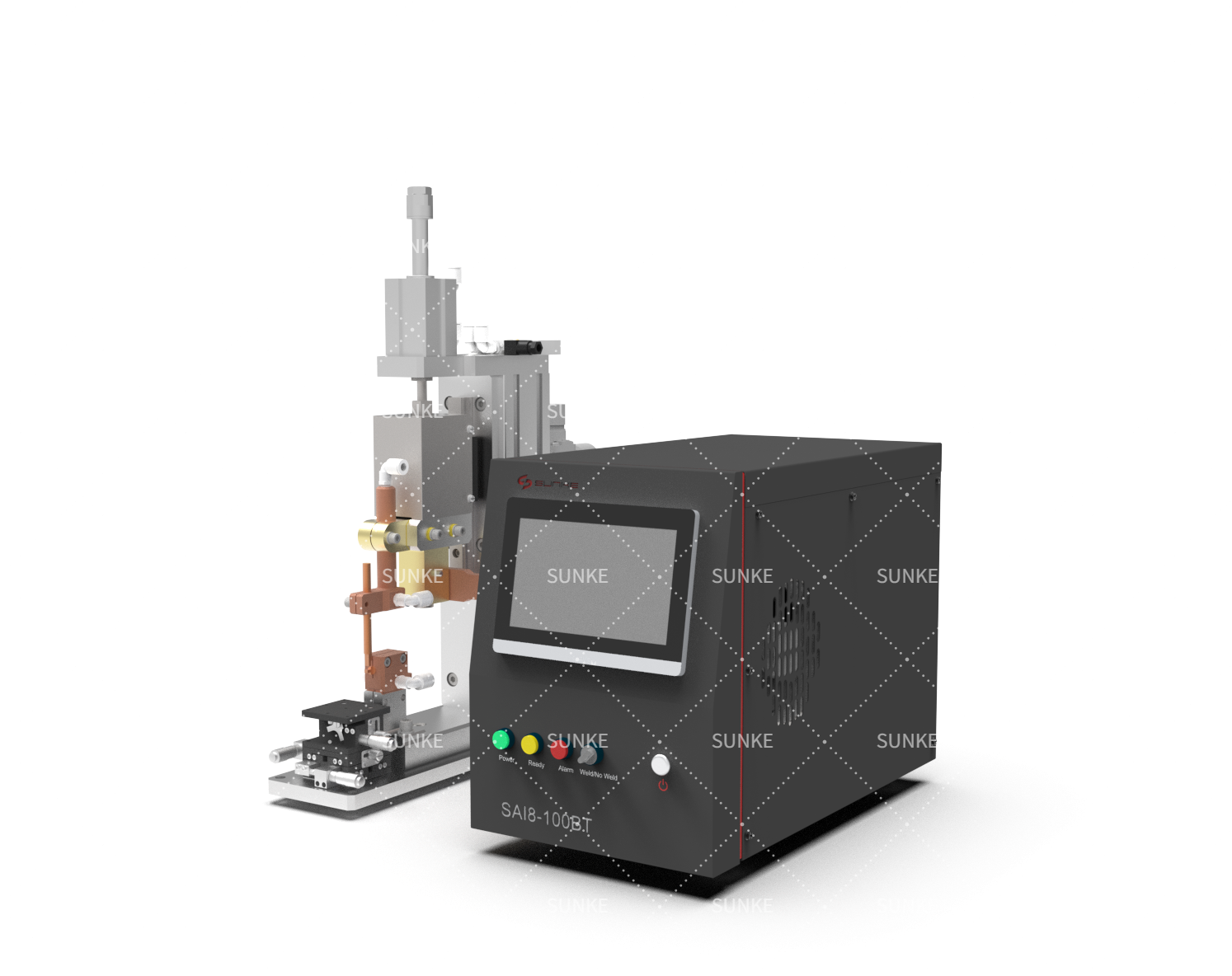

Introducing SUNKE: Revolutionizing Precision Welding Systems

Release Time:

2025-08-16

At SUNKE, we understand the critical role that precision plays in modern manufacturing. Our brand is built on the foundation of innovation, quality, and efficiency, making us a leader in precision automated welding systems. Today, we want to introduce you to our reliable solutions that promise to transform your welding processes.

Touch Screen Interface: A User-Friendly Design for Simplified Operation

One of the standout features of SUNKE’s precision automated welding system is our intuitive touch screen interface. Designed with user-friendliness in mind, this interface simplifies the operation of our equipment, allowing for enhanced control. We believe that technology should empower users, not complicate tasks. With just a few taps, operators can adjust settings, monitor progress, and manage production with ease. This streamlined approach reduces training time and minimizes the risk of errors, ensuring that your team can focus on what truly matters: delivering high-quality products.

High Current Accuracy: Ensuring Consistent Welding Results

At the heart of our precision welding systems is the commitment to high current accuracy. With a remarkable 10A tolerance, our equipment guarantees consistent welding results across a variety of applications. This precision is essential, especially in industries like electronics, automotive, and medical device manufacturing, where even the smallest deviation can lead to significant issues. By utilizing our systems, you can expect optimal results that not only meet industry standards but also enhance your overall production efficiency. We take pride in knowing that our technology supports your commitment to quality and reliability.

Unmatched Control Precision: Meticulous Management of Every Weld Process

What sets SUNKE apart in the realm of precision automated welding systems is our unmatched control precision. Our technology delivers an astounding 0.1ms accuracy, allowing for meticulous management of every weld process. This level of precision is critical when dealing with intricate welding tasks. By investing in our precision welding systems, you can rest assured that each weld is executed flawlessly, reducing scrap rates and ensuring that your production line operates at peak efficiency. Our solutions are designed to adapt seamlessly to various welding requirements, offering flexible settings that cater to your specific needs.

Conclusion

Overall, Among precision automated welding systems, SUNKE takes great pride in being at the forefront. Our commitment to innovation and quality is evident in every aspect of our equipment, from the user-friendly touch screen interface to the unmatched control precision we offer. By investing in our precision welding system, you are not just upgrading your equipment; you are enhancing your entire production process. Join us on this journey towards greater efficiency, accuracy, and control in your manufacturing operations. Experience the SUNKE difference today!