SUNKE: Your Go-To Brand for Advanced Welding Solutions

Release Time:

2025-08-16

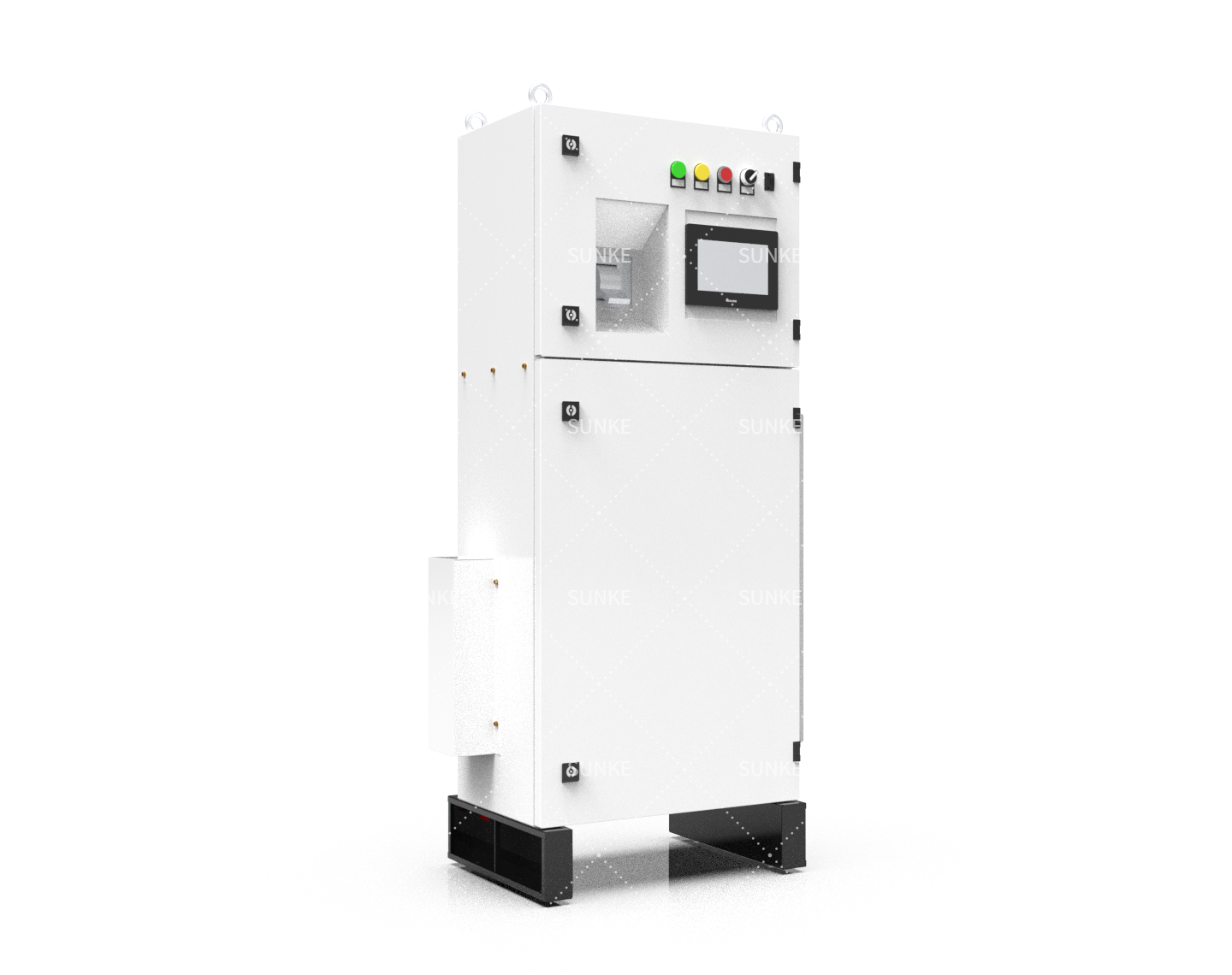

At SUNKE, we pride ourselves on being at the forefront of welding technology, delivering high-performance solutions tailored for diverse industrial needs. Our flagship product, the MFAC Welding Controller, exemplifies our commitment to innovation and quality. This article explores the features and advantages of our welding controllers, designed for spot welding, projection welding, and seam welding across various metal materials.

Unmatched Performance with Our MFAC Welding Controllers

Our MFAC welding controllers are purpose-built for industries requiring adaptable solutions. With a focus on performance and reliability, these controllers are the ideal choice for automated production lines, manual operations, and fixed spot welding systems. By integrating reliable technology, we ensure that our weld controllers meet the dynamic demands of modern manufacturing.

One of the standout features of our MFAC welding controllers is their ability to deliver consistent and high-quality welds. The controllers excel in applications where AC power characteristics are preferred, making them perfect for processes that require reduced expulsion and smooth current waveforms. This ensures that the welding process remains efficient and effective, resulting in clean welds with minimal spatter. With our MFAC welding controllers, you can trust that your welding projects will yield superior results.

Flexibility and Adaptability for Diverse Applications

In today’s fast-paced industrial environment, flexibility is key. Our medium-frequency AC resistance welding controllers are specifically designed to handle the dynamic needs of various applications. Whether you’re working on intricate projects that require precision or large-scale production runs, our weld controller adapts seamlessly to your requirements.

The absence of a polarity effect in our MFAC welding controllers is another significant advantage. This feature leads to stable, clean welds, making our controllers particularly beneficial for industries where quality is non-negotiable. By choosing our MFAC welding controllers, you gain a robust solution that enhances productivity while reducing operational costs.

Cost Efficiency Without Compromising Quality

At SUNKE, we understand that cost efficiency is a critical consideration for businesses. Our MFAC welding controllers strike an exceptional balance between performance and affordability. Designed for maximum durability and reliability, these weld controllers are a smart investment for any manufacturing setup.

By utilizing our medium-frequency AC welding controllers, industries can achieve cost savings through reduced material waste and efficient energy consumption. Our controllers are engineered to optimize the welding process, making them a valuable addition to your operations. With SUNKE, you don’t have to compromise quality for cost—our MFAC welding controllers deliver both.

Conclusion

In summary, SUNKE is committed to providing advanced welding solutions that meet the evolving demands of the industry. Our MFAC welding controllers stand out as a reliable choice for various welding applications, offering unmatched performance, flexibility, and cost efficiency. Whether you’re involved in automated production lines or manual operations, our welding controllers are designed to enhance your productivity while ensuring high-quality results.

As we continue to innovate and expand our product offerings, we invite you to explore the advantages of our MFAC welding controller. Partner with SUNKE today and elevate your welding processes to new heights!