SUNKE's Precision Welding Solutions: The Future of High-Accuracy Welding Systems

Release Time:

2025-06-13

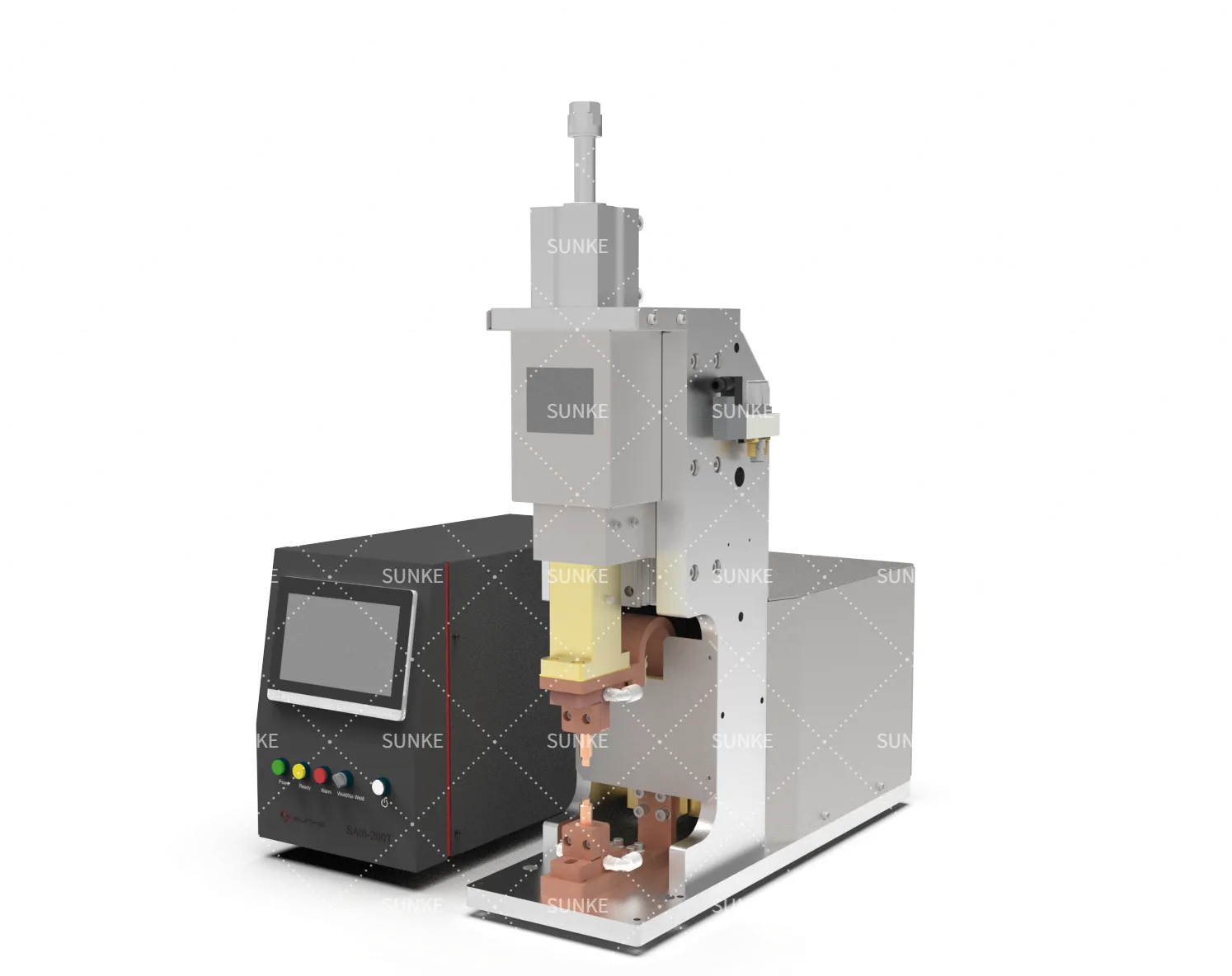

In the ever-evolving world of manufacturing, precision is key, and welding is no exception. SUNKE has redefined the way industries approach precision welding systems by introducing cutting-edge technologies that elevate performance and accuracy. As a leader in welding innovation, SUNKE's precision automated welding system offers unmatched precision, reliability, and versatility for a wide range of applications.

What Makes SUNKE's Welding Systems Stand Out?

At SUNKE, we believe in pushing the boundaries of welding technology. Our precision welding systems feature self-developed resistance welding controllers that allow for superior control over the welding process. These controllers are the heart of our systems, ensuring consistent, high-quality results with minimal human intervention.

Additionally, SUNKE integrates advanced hardware and software for seamless operation. The combination of these elements allows our systems to operate with exceptional efficiency, reducing downtime and maximizing productivity. Our precision automated welding systems are designed with the future in mind, offering high performance and reliability across a range of industries.

Tailored Solutions for Every Welding Requirement

No two industries are the same, which is why SUNKE offers tailored solutions to meet unique welding needs. Whether you're in automotive, electronics, or aerospace, our systems can be customized to suit your specific requirements. Our ability to adapt both hardware and software ensures that each precision welding system we provide is a perfect match for the task at hand.

With over 60 industries relying on our technology, SUNKE's precision automated welding systems are flexible enough to handle diverse applications. Whether it's joining thin metal sheets or welding complex components, we have the right solution for every challenge.

Optimizing Efficiency with SUNKE's Welding Technology

Efficiency is at the core of SUNKE's design philosophy. Our precision welding systems are equipped with advanced features that allow for the fine-tuning of process parameters. This results in improved welding quality, faster production times, and reduced waste. By optimizing these parameters, we can solve even the most complex welding challenges with precision and consistency.

The long-term benefits of optimized parameters are significant. Not only do they contribute to superior weld quality, but they also improve cost-efficiency and production timelines. With SUNKE's precision automated welding systems, manufacturers can expect reduced rework, lower material costs, and an overall increase in operational efficiency.

Conclusion

SUNKE's precision welding systems and precision automated welding systems set the standard for high-accuracy welding solutions. Through self-developed technology, tailored customization, and optimized process parameters, we are shaping the future of welding. By choosing SUNKE, industries can achieve unparalleled quality, efficiency, and reliability in their welding processes.