Presenting SUNKE: The Ultimate Industrial Welding Solution

Release Time:

2025-07-23

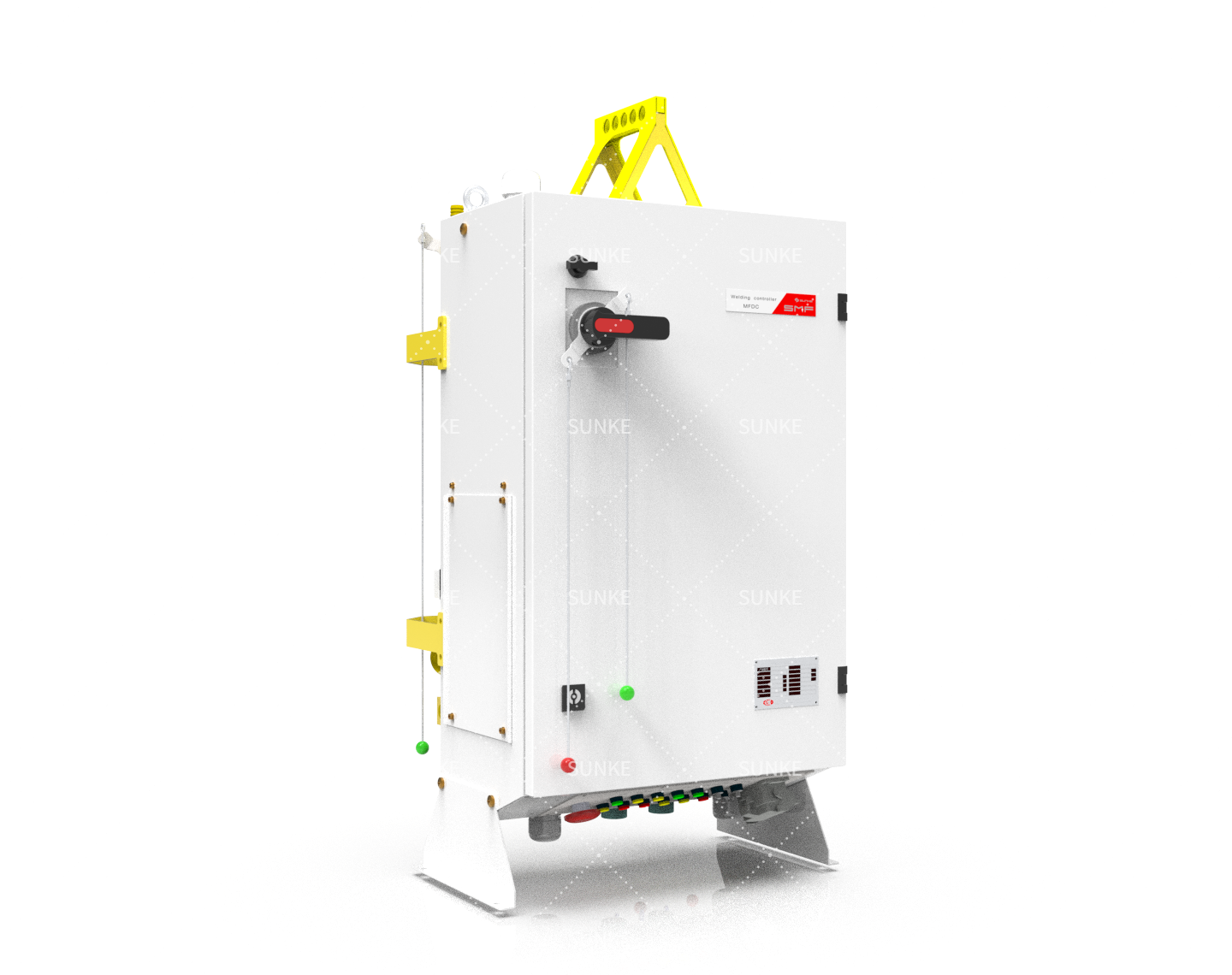

We take great delight in the fact that SUNKE has pioneered reliable industrial welding technology. Presenting the MFDC welding controller, a key component for contemporary welding applications, the result of our unique approach and dedication to quality. Developed to address the varied requirements of certain industrial sectors, our medium frequency DC welding controllers are the subject of this article's examination of their characteristics and advantages.

The Power of Medium Frequency DC Welding Controllers

Our medium frequency DC welding controllers are engineered to deliver superior performance in various welding applications. These controllers work in conjunction with welding machines, enhancing their capabilities and ensuring precise welds in challenging environments. Ideal for industries that require high accuracy, our MFDC welding controllers are widely used in spot welding, projection welding, and seam welding for various metallic materials. By utilizing advanced modular design, our controllers provide unmatched compatibility across different welding setups. Whether you’re working with automated systems or manual setups, SUNKE’s medium frequency DC welding controllers adapt seamlessly to your operational needs. This flexibility makes them perfect for fixture-based spot welding systems, ensuring efficient and reliable results every time.

Key Specifications of Our MFDC Welding Controllers

When selecting a welding controller, understanding its specifications is crucial. Our MFDC welding controller operates on an input voltage of 3-phase AC 380V~480V±10%. This robust power supply guarantees a stable operation, which is essential for maintaining high-quality welds. The output frequency options of 1000Hz, 1800Hz, and 6000Hz, combined with PWM output voltage of 500V, allow for precise control over the welding process. With a duty cycle of 10%, our controllers can handle demanding tasks without overheating, thanks to the efficient cooling methods available—air-cooled or water-cooled. Additionally, our controllers support a maximum output current range from 400A to 3600A, making them suitable for a wide variety of welding applications. The ability to program up to 256 weld schedules empowers operators to customize their welding processes, ensuring optimal results for each project.

Why Choose SUNKE for Your Welding Needs

Choosing SUNKE means opting for reliability, innovation, and efficiency. Our medium frequency DC welding controllers stand out in the market for several reasons. Firstly, our commitment to quality ensures that every controller undergoes rigorous testing to meet industry standards. We understand that in the welding industry, precision is non-negotiable, and our controllers deliver that consistently. Moreover, our customer support team is dedicated to assisting you throughout your journey. Whether you need help with installation, programming, or maintenance, we’re here to ensure your operations run smoothly. With SUNKE, you’re not just purchasing a product; you’re investing in a partnership that prioritizes your success.

Conclusion

In the ever-evolving landscape of industrial welding, having the right tools is essential. SUNKE’s MFDC welding controller brings together advanced technology and user-friendly design, making it an invaluable asset for any welding operation. By utilizing our medium frequency DC welding controllers, you’ll enhance your welding capabilities, ensuring precision and reliability across various applications. Join us at SUNKE and experience the future of welding technology today!