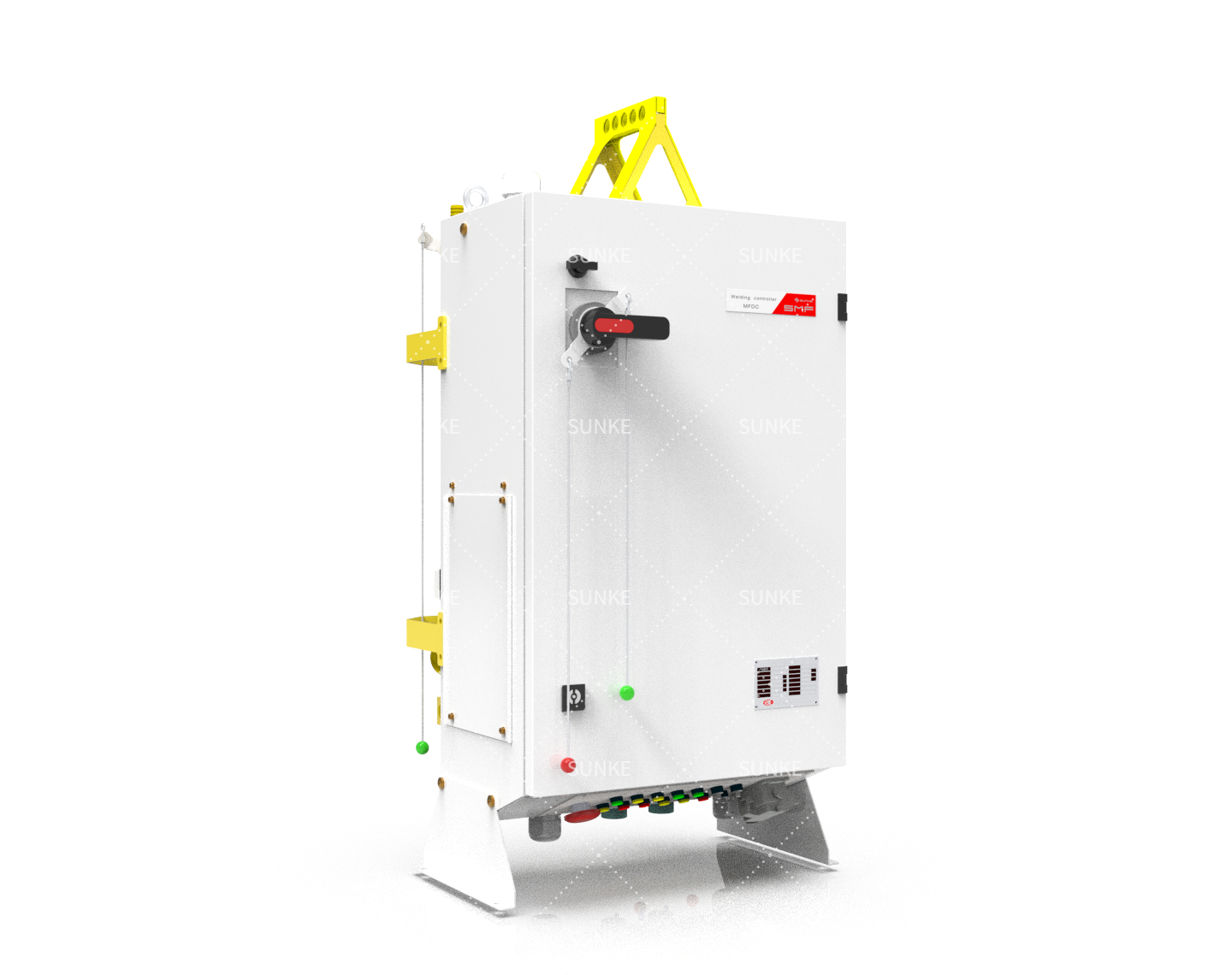

MFDC Welding Controller

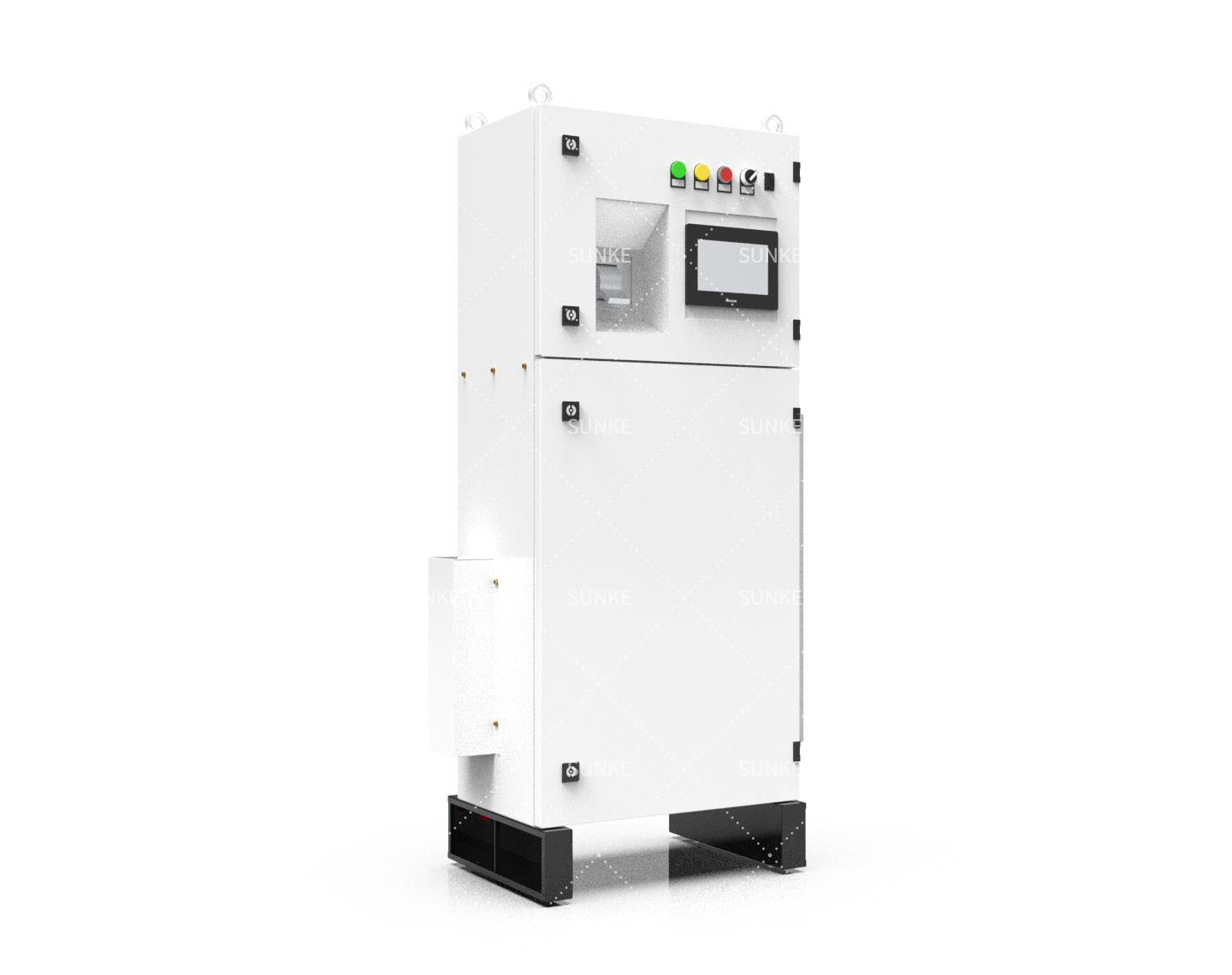

Medium frequency DC welding controllers are used in conjunction with a welding machine, widely applied in precision industrial fields. With advanced modular design, they ensure compatibility with diverse welding applications such as spot welding, projection welding, and seam welding for various metallic materials. These medium frequency DC welding controllers are ideal for both automated and manual welding setups, as well as fixture-based spot welding systems. Designed to deliver precise DC welding current control, these controllers support primary/secondary current control modes. With options for air cooling/water cooling, they adapt seamlessly to different operational environments. The integration of flexible communication interfaces ensures effortless connectivity with various industrial field buses, enabling real-time monitoring and control. Sunke's medium-frequency DC resistance welding controllers set the benchmark in the industry for reliability and performance, meeting the demanding needs of modern welding processes. Whether you require an MFDC welding machine or a comprehensive middle frequency DC welding controller solution, Sunke’s products ensure precision, efficiency, and durability, tailored for industrial challenges today.

Product Advantages

Product Parameters

| SMF Series Medium Frequency DC Resistance Welding Controller | |

| Input Voltage | 3phase AC 380V~480V±10% |

| Output Voltage | 1000Hz / 1800Hz / 6000Hz, PWM 500V |

| Duty Cycle(ED) | 10% |

| Maximum Output Current (A) | 400 / 600 / 800 / 1200 / 1600 / 2400 / 3600 |

| Cooling Method | Air Cooled/Water Cooled |

| Weld Schedule | 256 |

| Control Method | KSR/KUR/PHA/SAIRS |

| Secondary Feedback | Yes |

| Solenoid Valve Control | DC24V |

| Proportional Valve Control | 0~10V , 4-20mA / 0~20mA |

| Ethernet Function | Yes |

| Fieldbus Option | Digital I/O/ Profinet / Profibus / Devicenet / EIP / CClink |

Discover the future of medium frequency DC welding with

Sunke's cutting-edge solutions today!

High Welding Efficiency and Quality

Our controllers can optimize heat input, ensuring consistent weld quality with reduced energy consumption.

Patented Adaptive Technology

Enhances process stability by automatically adjusting to varying conditions during welding.

Extensive Weld Schedules

Supports more than 256 programmable weld schedules, offering unmatched flexibility for complex welding tasks.

Industrial Bus Connectivity

Effortlessly connects to popular industrial field buses, streamlining automation and system integration.

Sunke's medium-frequency DC resistance welding controllers set the benchmark in the industry for reliability and performance, meeting the demanding needs of modern welding processes. Whether you require an MFDC welding machine or a comprehensive middle frequency DC welding controller solution, Sunke's products ensure precision, efficiency, and durability, tailored for industrial challenges today.