SUNKE's MFAC Welding Controllers: Precision for Every Application

Release Time:

2025-09-28

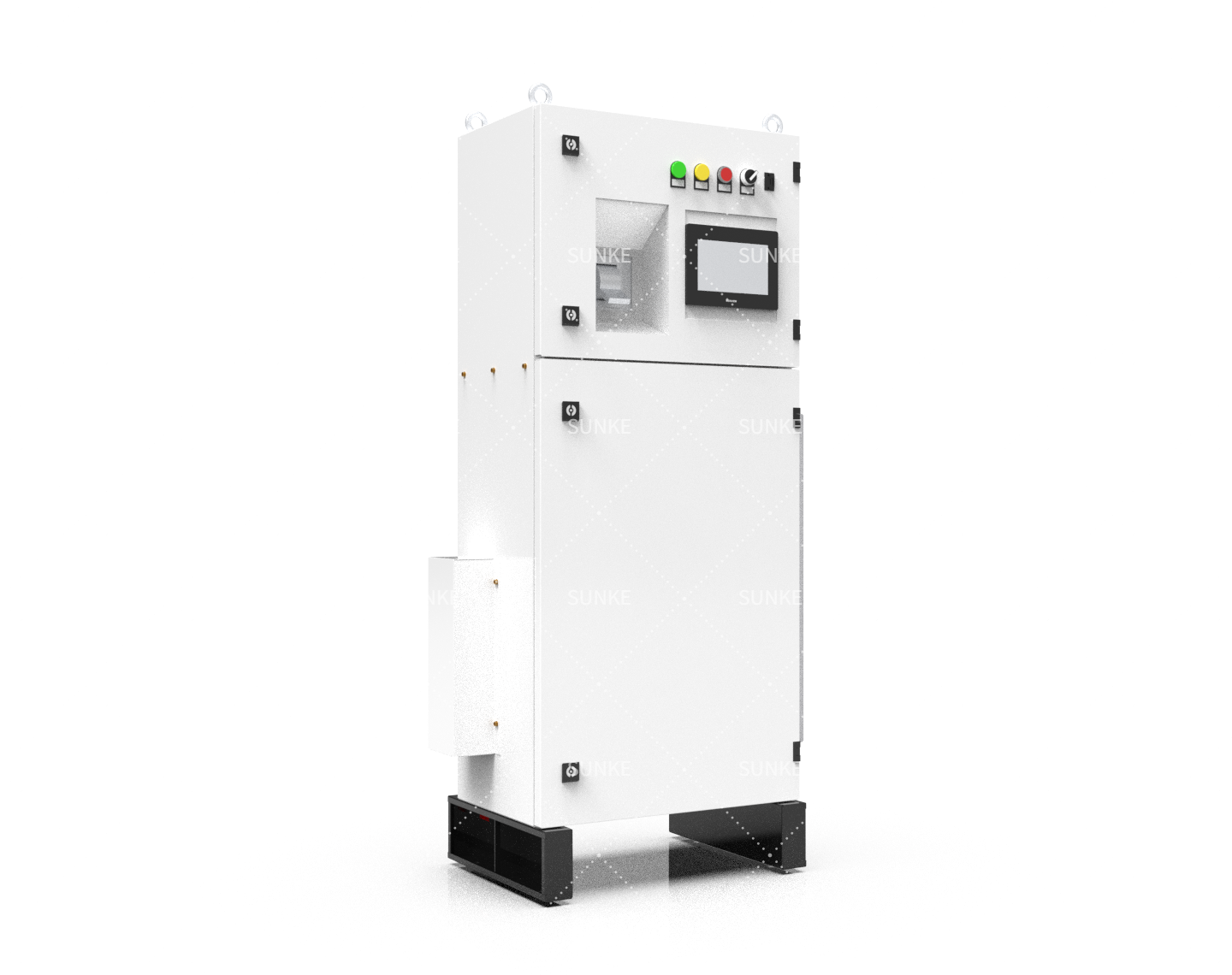

In the ever-evolving landscape of the welding industry, MFAC welding controllers stand out for their adaptability and precision. MFAC, or Medium Frequency Alternating Current, technology is designed to meet the rigorous demands of modern manufacturing. These controllers excel in various welding applications, including spot welding, projection welding, and seam welding, making them essential for industries that require versatile solutions. At SUNKE, we understand the importance of these capabilities, which is why our MFAC resistance welding solutions are engineered to deliver exceptional performance.

Advantages of SUNKE's MFAC Resistance Welding Solutions

SUNKE's MFAC welding controllers provide numerous advantages that enhance the quality of welds. One of the key performance features is the reduction of expulsion, ensuring that welds are cleaner and more efficient. The smooth current waveforms generated by our controllers allow for stable and consistent welding, significantly reducing the risk of defects. This translates into stable, clean welds with minimal spatter, which is crucial for improving overall product quality. When you choose SUNKE, you're investing in technology that prioritizes both performance and reliability.

Optimizing Production with SUNKE's Controllers

Efficiency is paramount in today's manufacturing environment, and SUNKE's MFAC welding controllers are designed to optimize production processes. Our controllers enhance efficiency in automated production lines, seamlessly integrating with existing systems to streamline operations. This adaptability allows for quick adjustments to meet dynamic welding needs without compromising on quality.

Moreover, SUNKE's solutions offer a cost-effective approach to welding. By balancing performance and flexibility, our MFAC resistance welding controllers provide manufacturers with the tools they need to maximize productivity while minimizing costs. Whether you're operating a fully automated line or handling manual operations, our technology is tailored to meet your specific requirements.

Conclusion: Choose SUNKE for Reliable MFAC Welding Solutions

In conclusion, SUNKE's MFAC welding controllers represent a significant advancement in welding technology. With their adaptability for various applications, impressive performance features, and efficiency enhancements, our solutions are designed to meet the diverse needs of the industry. By choosing us, you're not just investing in a product; you're partnering with a brand committed to delivering quality, reliability, and innovation. Elevate your welding operations with our MFAC resistance welding solutions and experience the difference that precision engineering can make in your manufacturing processes.

Previous: 无

Next: Unlock High-Efficiency Welding with SUNKE's MFDC Welding Solutions