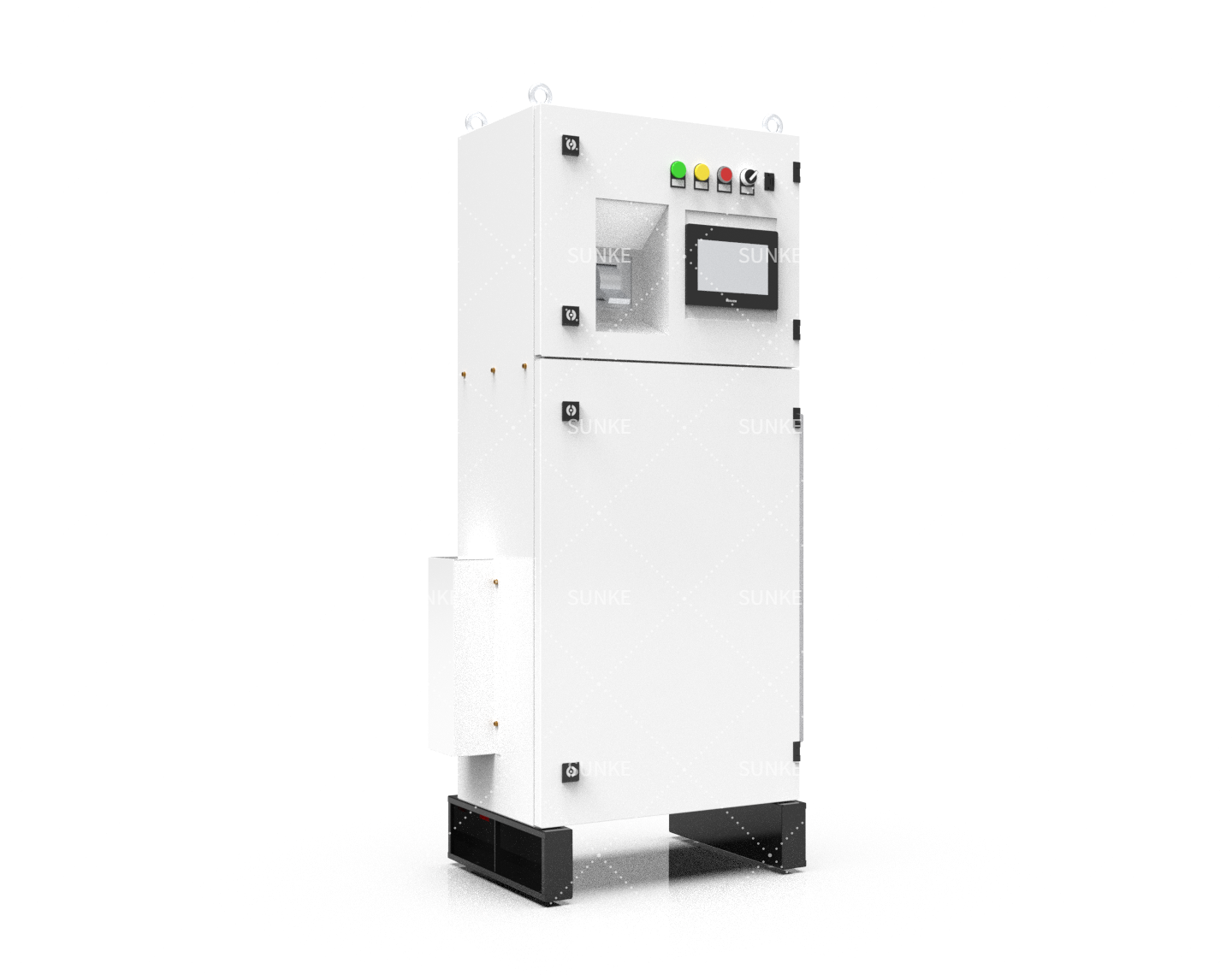

MFAC Welding Controller

Our MFAC welding controllers are purpose-built for industries requiring adaptable solutions for spot welding, projection welding, and seam welding across a wide range of metal materials. With a focus on performance and reliability, Sunke’s middle frequency AC welding controllers are the ideal choice for automated production lines, manual operations, and fixed spot welding systems. MFAC welding controllers excel in applications where AC power characteristics are preferred, such as processes demanding reduced expulsion, smooth current waveforms, and simplified polarity handling. The absence of a polarity effect ensures stable, clean welds with minimal spatter, providing distinct advantages in certain industrial scenarios. Sunke’s medium-frequency AC resistance welding controllers are specifically designed to handle dynamic welding needs while offering a balance of performance, flexibility, and cost efficiency. Choose our mid-frequency AC weld controllers for applications that demand a robust and reliable solution tailored to AC welding processes.

Product Advantages

Product Parameters

| SVF Series Medium Frequency AC Resistance Welding Controller | |

| Input Voltage | 3phase AC 380V~480V±10% |

| Output Voltage | 15~400Hz ,PWM 500~650V |

| Duty Cycle(ED) | 5% / 10% |

| Maximum Output Current (A) | 400 / 800 / 1000 / 1200 / 1600 / 2400 / 3600 / 4800 |

| Cooling Method | Air Cooled/Water Cooled |

| Weld Schedule | 256 |

| Control Method | KSR/KUR/PHA/SAIRS |

| Secondary Feedback | Yes |

| Solenoid Valve Control | 24 |

| Proportional Valve Control | 0~10V , 4-20mA / 0~20mA |

| Ethernet Function | Yes |

| Fieldbus Option | Digital I/O/ Profinet / Profibus / Devicenet / EIP / CClink |

Key Features of MFAC welding controller

Modular Design: Tailored for flexibility, allowing seamless integration into diverse welding setups.

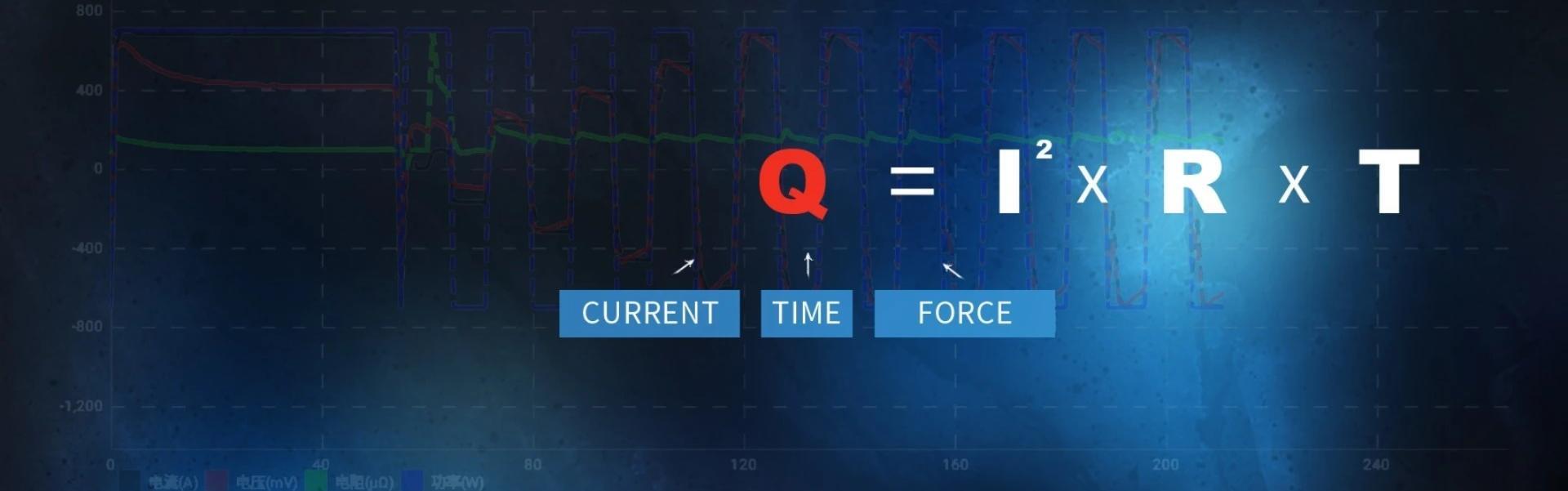

Primary and Secondary Current Control: Enables precise control for consistent weld quality.

Cooling Options: Air cooling and water cooling configurations meet specific operational requirements.

Flexible Communication Interface: Facilitates real-time connectivity with various industrial field buses.

Product Advantages

Transform your welding operations with Sunke’s MFAC controllers – the versatile choice for industrial excellence!

No Polarity Effect: Unique to MFAC technology, reducing spatter and expulsion for superior weld integrity.

High Efficiency and Quality: Ensures consistent weld strength and minimizes energy waste.

Advanced Adaptive Technology: Automatically adapts to process variations, ensuring reliability.

256+ Weld Schedules: Stores extensive programmable schedules for complex or diverse projects.

Field Bus Compatibility: Easily integrates with industrial automation systems.

Sunke’s medium-frequency AC resistance welding controllers are specifically designed to handle dynamic welding needs while offering a balance of performance, flexibility, and cost efficiency.

Choose our mid-frequency AC weld controllers for applications that demand a robust and reliable solution tailored to AC welding processes.

Sunke's medium-frequency AC resistance welding controllers are specifically designed to handle dynamic welding needs while offering a balance of performance, flexibility, and cost efficiency. Choose our mid-frequency AC weld controllers for applications that demand a robust and reliable solution tailored to AC welding processes.