Precision and Efficiency with SUNKE's Medium Frequency DC Welding Controllers

Release Time:

2025-09-27

In modern industrial applications, resistance welding has become a crucial method for joining metals with precision and reliability. Medium frequency DC welding (MFDC) has emerged as a revolutionary technology that enhances the efficiency and effectiveness of these processes. With SUNKE leading the charge in MFDC welding controllers, industries can achieve higher precision, faster operations, and reduced energy consumption, making it an ideal choice for industries demanding the highest standards.

The Role of Medium Frequency DC Welding in Precision Industries

MFDC welding controllers offer remarkable control over the welding process, ensuring consistent and accurate welds. By using medium frequency DC welding, businesses in industries such as automotive, electronics, and manufacturing can benefit from quicker cycle times and more precise welds, minimizing waste and improving product quality.

Advanced Design Features of SUNKE's MFDC Welding Controllers

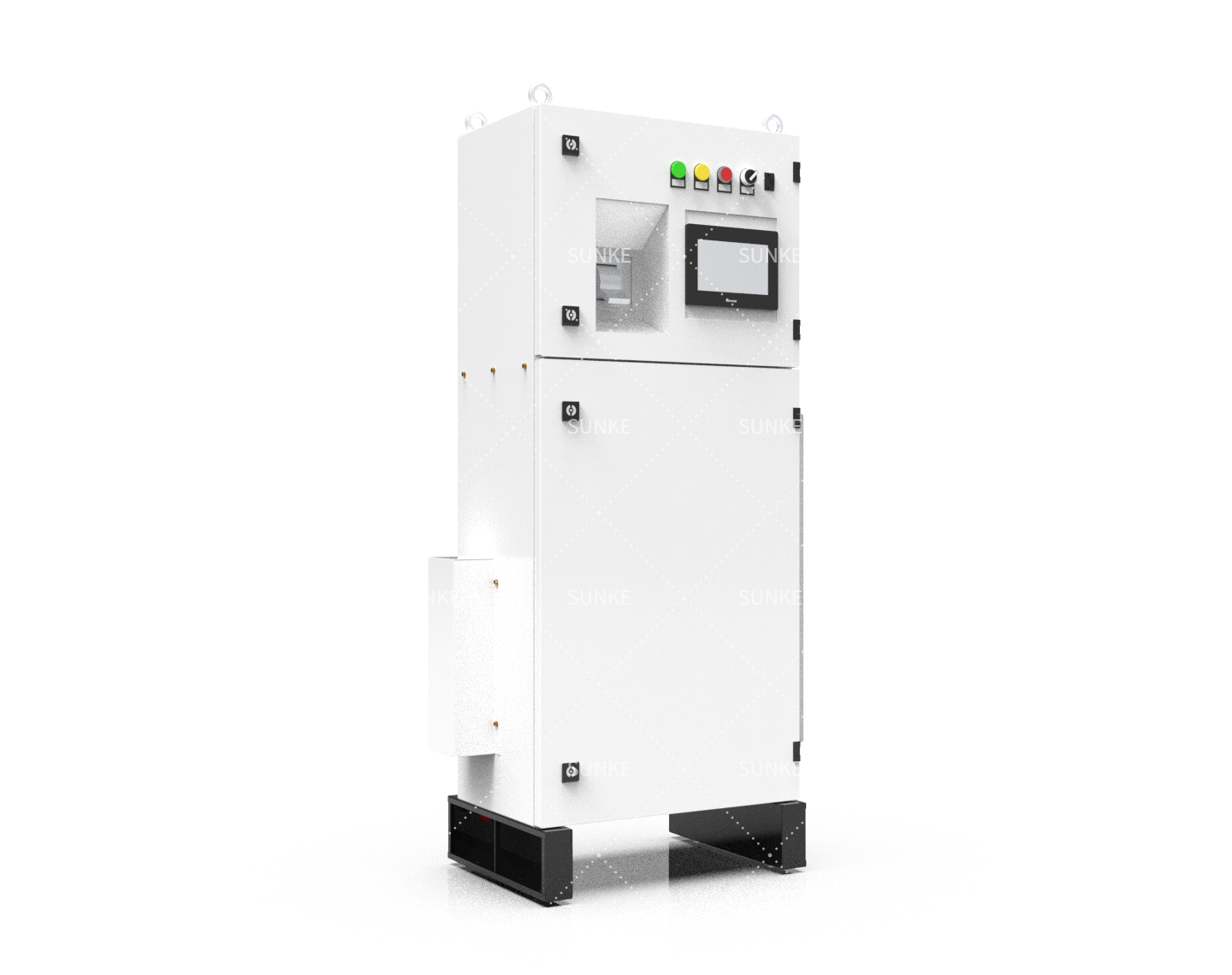

SUNKE's MFDC welding controllers are designed with cutting-edge technology to cater to a wide range of industrial welding needs. These controllers excel in applications such as spot welding, projection welding, and seam welding, all critical for industries requiring high-quality welds on various metallic materials.

One of the standout features of our MFDC controllers is their modular design, which allows them to be customized for both automated and manual setups. This flexibility makes them a perfect solution for industries with diverse production needs. Whether integrated into automated systems or used for fixture-based manual setups, SUNKE's controllers ensure optimal compatibility and functionality, adapting to different operational environments with ease.

Moreover, the MFDC welding controllers are designed to operate in both air and water-cooled systems, further improving their versatility and making them ideal for environments with varying cooling requirements.

Reliability and Performance: Why Choose SUNKE's Medium Frequency DC Controllers?

At SUNKE, we prioritize the reliability and performance of our MFDC welding controllers. Our controllers provide precise control over DC welding currents, enabling industries to achieve the exact power needed for each welding application. The ability to fine-tune these settings ensures that every weld is consistent and of the highest quality.

Another benefit of our MFDC welding controllers is their real-time monitoring and flexible communication interfaces. These features enable seamless integration with industrial field buses, allowing operators to monitor the welding process and make adjustments in real-time, which ultimately boosts productivity and reduces downtime.

Additionally, SUNKE's controllers are built to withstand demanding industrial environments, with robust cooling options and advanced current control mechanisms. This ensures that operations run smoothly, minimizing any risk of failure and extending the lifespan of the equipment.

Conclusion: Unlock the Potential of Your Welding Operations with SUNKE

Choosing SUNKE means choosing a welding technology partner that offers cutting-edge solutions for medium frequency DC welding. Our MFDC welding controllers ensure precision, adaptability, and energy efficiency, helping your operations thrive while reducing costs. Whether you're looking for spot welding solutions or comprehensive welding systems, SUNKE provides the tools you need for consistent, high-quality results.