Capacitive Discharge Welder

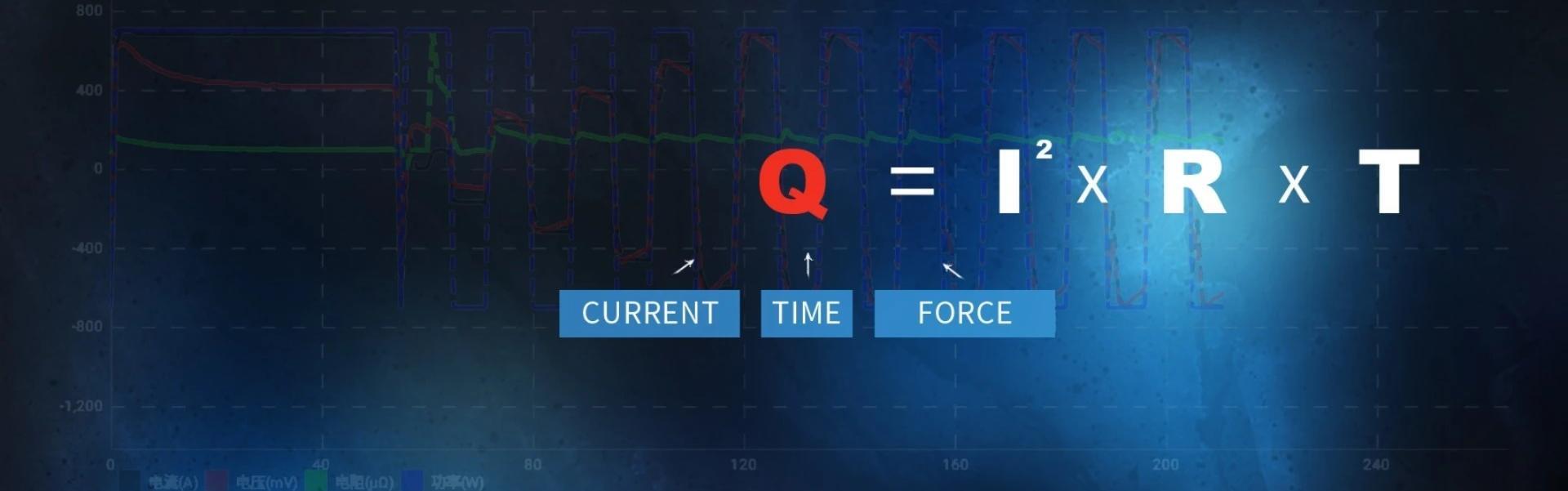

Precision Welding with Stored Energy Technology Our capacitor discharge welders (CD welders) leverage advanced electronic voltage elevation and constant-current charging circuit technology to store electrical energy in capacitors. This stored energy is discharged instantaneously to the workpiece via a pressure mechanism, melting the contact metal with welding currents ranging from tens to hundreds of thousands of amperes in an incredibly short time. The result is minimal heat loss and perfect welds, making it ideal for high-precision applications.

Product Advantages

Product Parameters

| SCD Series Storaged Energy Resistance Welding Controller | |

| Input Voltage | 3phase AC 110V~480V±10% |

| Output Voltage | 15~400Hz ,PWM1000V |

| Duty Cycle(ED) | 10% |

| Energy (KJ) | 10 / 20 / 30 / 40 |

| Cooling Method | Water Cooled |

| Weld Schedule | 32 / 128 |

| Control Method | KSR/KUR/PHA/SAIRS |

| Secondary Feedback | Yes |

| Solenoid Valve Control | 24 |

| Proportional Valve Control | 0~10V/4-20mA/0~20mA |

| Ethernet Function | No |

| Fieldbus Option | RS422 |

Low Demand on the Grid:With uniform load characteristics, these energy storage welders operate efficiently in environments with limited grid power supply.

High-Quality Welds:Achieves excellent results with precise heat input, reducing defects and ensuring consistent weld integrity.

Stable Current Output: Advanced technology ensures steady and reliable current delivery throughout the process.

Consistent Penetration: Delivers uniform penetration, especially suitable for applications requiring precise and repeatable welds.

Capacitor discharge projection welding machines for nut welding and precision fabrication.

Stored energy welding systems for industries requiring minimal energy consumption and exceptional results.

CD welding machines optimized for fast, repeatable, and high-quality welds.

Our capacitor discharge welding machines represent the pinnacle of stored energy welding technology, combining efficiency, precision, and reliability to meet the challenges of modern manufacturing.

This method of welding, also known as capacitor discharge welding, is particularly advantageous for welding nuts, studs, and other components where traditional power sources may fall short. It is highly effective in scenarios where grid power is unstable or insufficient. Furthermore, the quick discharge cycle reduces heat-affected zones, preserving the integrity of surrounding materials and enhancing overall weld quality.

Experience superior performance with our advanced CD welders today!